Your cart is currently empty!

What are Bullets Made of?

From hunters to law enforcement officers to everyday civilians, we’re all at some level intrigued by bullets. While their function and impact are clear, the material composition of bullets is often a mystery to those who don’t manufacture or reload them. So, let’s break it down simply and answer the common question: “What are bullets made of?”

The Short Answer: A bullet isn’t just a solid piece of metal. Modern bullets primarily consist of a lead core encased in a jacket made from copper or a copper alloy. This combination provides optimal weight, balance, and density, allowing bullets to travel long distances with precision and minimal barrel wear. Once complete, the bullet is fitted into a casing with gunpowder and a primer, creating live ammunition ready for firing.

Having provided the high-level answer, let’s explore the interesting history and evolution of bullet manufacturing further. Bullets embody our technological advancements and understanding of materials science over centuries.

The History: What Were Bullets Originally Made Of?

In our journey of understanding what bullets are made of, let’s start from the very beginning.

The Dawn of Bullets: From Stone to Lead

The earliest projectiles, referred to as a “hand cannon”, were made of stone. As firearms technology progressed, lead became the material of choice for bullets due to its abundance, ease of molding, and excellent ballistic properties. These early bullets, typically round lead balls, provided the necessary weight and density for effective range and impact. Pure lead projectiles played a critical role in many historic conflicts, including battles on American soil in the 18th and 19th centuries. However, while effective, this simplicity came with limitations that would drive further innovations in bullet design.

Challenges and Innovations: The Emergence of the Minie Ball

The spherical shape of early lead bullets often led to poor fit in rifle barrels, creating unpredictable trajectories. Marksmen faced the challenge of achieving consistent accuracy, which led to the invention of the Minie ball in the mid-19th century. This bullet, with its conical shape and hollow base, provided a tighter barrel fit, greatly improving accuracy. The Minie ball proved crucial in the American Civil War, as it allowed for greater precision over longer distances. Still, lead’s inherent limitations spurred further innovation in bullet design and materials.

Advancements and Diversification: Exploring New Bullet Materials

As firearm technology evolved, so did the demand for more advanced bullet designs. Manufacturers began experimenting with materials that could better withstand high-velocity firing and offer improved performance. This experimentation led to the creation of bullet jackets made from metals like copper, which enhanced durability and reduced fouling in the barrel. The result? A new era of bullets capable of greater accuracy, stability, and safety for the shooter.

Every stage of this historical progression contributed to what we now recognize as the modern bullet. It is remarkable to think that the simple round ball has evolved into today’s highly sophisticated and diverse range of bullet types. And the story isn’t done yet; the continuous enhancements in bullet creation techniques and materials are a testament to the never-ending quest for superior performance.

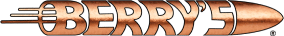

The Evolution: What Are Cast, Jacketed, and Plated Bullets Made Of?

We’ve looked back at bullet history and understood how far things have come. Now, let’s take a step forward into the present and explore the three most common types of bullets today: cast, jacketed, and plated.

Cast Bullets: Economical and Efficient

Components: Molded Lead or Lead Alloy

Cast bullets are the simplest form of bullets and are made by pouring molten lead or a lead alloy into a mold, or “cast.” Thanks to their ease of production, cast bullets are very affordable, making them a favorite among budget shooters. However, they lead to significant lead fouling in the barrel, an issue that requires regular maintenance and cleaning.

Jacketed Bullets: Robust and Versatile

Components: Lead Core, Copper or Copper Alloy Jacket

Next in line are the jacketed bullets, which have a copper jacket surrounding a lead core. The key advantage of a jacket is that it allows the bullet to maintain its structural integrity even at higher velocities without compromising accuracy. This makes jacketed bullets a top choice for hunting bullets and in other situations that require more power. However, their advanced design and the added manufacturing steps also mean a higher price tag compared to the cast bullets.

Plated Bullets: Balancing Performance and Value

Components: Lead Core, Electroplated Copper Coating

Lastly, we have plated bullets, which cleverly strike a balance between the performance of jacketed bullets and the affordability of cast bullets. They consist of a lead core just like in jacketed bullets, but instead of a harder metal jacket, a thin layer of copper is electroplated around the core, completely covering it. The result is significantly reduced gun barrel fouling, comparable to jacketed bullets without tearing a hole in your wallet.

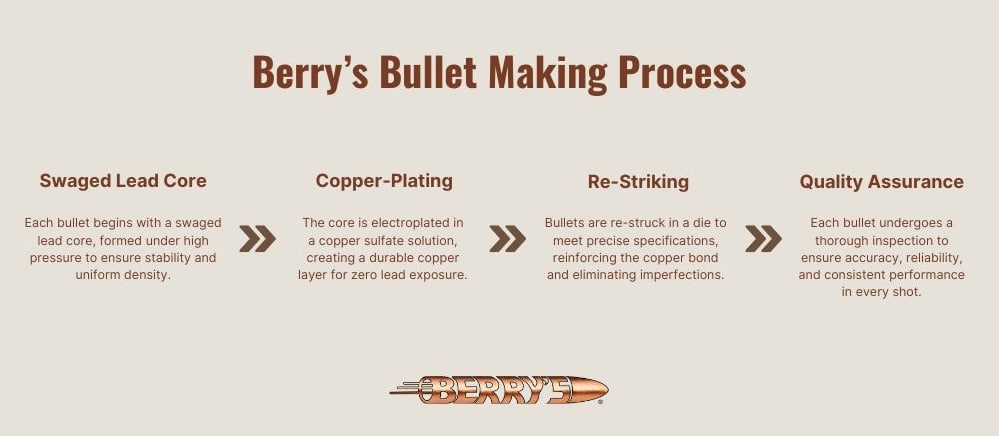

A Look Inside Berry’s Bullet Making Process

Now that we have a broader understanding of what typical bullets are made of, let’s take a look at the bullet-making process at Berry’s Bullets to give you a better idea of all that goes into bullet manufacturing.

Starting with a Solid Core

The creation of every bullet begins with a critical element – the core. Here at Berry’s, we use a technique called swaging to form a lead core. This method forms the core under high pressure which contributes to the bullet’s stability in flight by ensuring the uniform density of the core.

The Copper-Plating Process

Following the core formation, the next step is key to our bullet-making magic – electroplating. During this process, each swaged lead core is immersed in a copper cyanide solution, and an electric current is applied. This creates a controlled chemical reaction that deposits a thin yet sturdy layer of copper onto the lead core. The outcome? A bullet with zero lead exposure.

Re-Striking: Refined and Perfected

After electroplating, the bullets proceed to be re-struck. This involves passing the bullets through a die to achieve precise specifications, such as overall length and diameter. This re-striking process not only reinforces the bond between the copper and the lead core, but also smooths out any imperfections that may have occurred during electroplating.

Quality Assurance: The Final Step

Before shipping out, all our bullets undergo a rigorous inspection process. This step ensures that all bullets match our accuracy, reliability, and performance standards, providing consistent performance – round after round. This unique process and attention to detail sets Berry’s copper-plated bullets ahead of the pack. But don’t take our word for it.

Safety Tips for Using Lead-Based Bullets

Lead-based bullets offer excellent performance, but they also require careful handling. While our bullet-making process minimizes lead exposure, you should take precautions on your end as well. To limit exposure risks, wash hands thoroughly after handling bullets and clean firearms regularly to prevent lead buildup. If shooting indoors, choose well-ventilated areas or ranges with proper air filtration systems to reduce airborne particles. Following these simple practices helps shooters enjoy the benefits of lead-based bullets while staying safe.

Shop Superior Plated Bullets at Berry’s

In conclusion, knowing what bullets are made of—along with their evolution over time—provides valuable insight for shooters looking to enhance performance, precision, and safety. From the early days of lead bullets to today’s advanced plated designs, understanding bullet composition allows shooters to make informed choices for their unique needs. Berry’s bullets stand out for their superior quality, combining cutting-edge copper plating techniques with precision engineering, giving you a dependable and consistent shooting experience.

Ready to elevate your shooting? Explore our wide selection of superior plated bullets at Berry’s and discover the difference quality can make in every shot.