Your cart is currently empty!

How to Reload Bullets

Table of Contents:

- Preparing Your Brass Casings

- The Bullet Reloading Process

- Safety Considerations When Reloading

- Get Everything You Need for Shooting and Reloading from Berry’s

Reloading bullets is a rewarding process that allows shooters to create custom ammunition tailored to their specific firearms and needs. Whether you’re looking to save money on factory ammunition, improve accuracy, or develop loads for an obscure cartridge that’s hard to find, learning how to reload your own ammunition opens up new possibilities for shooting enthusiasts.

The Short Answer: Reloading bullets involves four main steps:

- Clean and prepare brass casings by inspecting, cleaning, and resizing them

- Install fresh primers in the primer pockets

- Add the proper powder charge according to published load data

- Seat the bullet to the correct depth and crimp if necessary

The reloading process requires attention to detail and an understanding of how different components work together. While factory ammunition serves most shooters well, many rifle and handgun owners find that crafting their own loads offers advantages in both performance and cost. For precision rifle competition shooters, customizing loads can significantly improve accuracy by matching ammunition exactly to their barrel. Those who shoot less common calibers or use older firearms might find reloading to be their best option when factory ammo is scarce or expensive.

Before diving into the reloading process, remember that safety must be your primary concern. Following established load data from a reloading manual is essential for creating ammunition that’s both safe and effective.

Preparing Your Brass Casings

Before loading your own ammunition, you need properly prepared brass casings. This foundation step impacts safety, accuracy, and the longevity of your reloaded rounds.

Inspecting Your Cases

Begin by carefully examining each fired case for signs of damage. Discard any brass with cracks, splits, or significant deformations. Look for cases with excessive pressure signs like flattened primer pockets or shiny ejector marks. For rifle cartridges, especially, inspect the case neck for signs of stretching or thinning.

Good quality brass can be reused multiple times, but each firing cycle puts stress on the material. S&W, Remington Magnum, and other high-pressure loads may show wear faster than standard-pressure rounds. New brass requires less preparation but still needs inspection before loading.

Cleaning Your Brass

Once inspected, brass casings need thorough cleaning:

- Use a brass cleaning tumbler with appropriate media (walnut shell, corn cob, or synthetic)

- Add a small amount of polish

- Tumble for 1-3 hours until the cases are clean

- Separate the brass from the media using a media separator

- Inspect cases again for any hidden defects revealed by cleaning

Clean brass ensures proper functioning of your dies and helps prevent contamination of your powder charge. It also makes visual inspection easier.

Resizing Your Cases

After cleaning, cases must be returned to proper dimensions:

- Apply a petroleum-based lubricant to the cases (essential for bottleneck rifle casings)

- Use a sizing die in your single-stage press or progressive press

- Resize the entire case body and neck

- For straight-walled pistol cases, a carbide die may eliminate the need for lube

- For bottlenecked rifle cases, ensure proper neck tension for holding bullets

This step ensures your ammunition will chamber correctly in any firearm of that caliber, not just the one it was fired in.

Case Trimming and Preparation

Brass stretches when fired, particularly in rifle cartridges. Use a case trimmer to maintain proper length:

- Measure each case with calipers

- Trim cases that exceed maximum length specifications from your reloading manual

- Deburr the case mouth inside and out after trimming

- Chamfer the inside edge slightly to help with bullet seating

For consistent primer ignition, clean the primer pockets to remove residue from fired primers. This step is especially important for precision rifle competition loads where consistency is crucial.

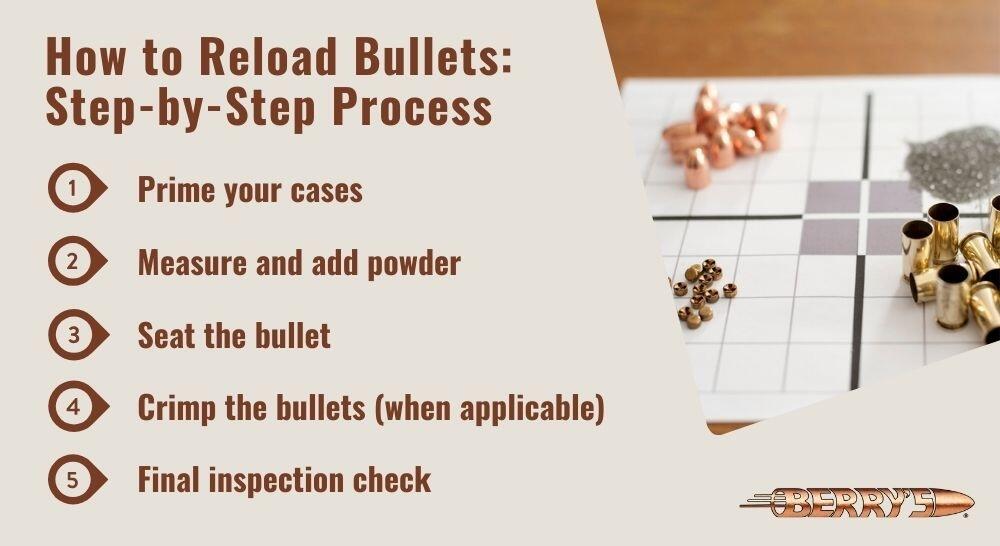

The Bullet Reloading Process

Once your brass casings are properly prepared, you’re ready to begin the actual reloading process. This multi-step procedure transforms your empty cases into complete ammunition.

Priming Your Cases

The first step is installing fresh primers into your prepared brass:

- Select the correct primer size and type for your load (small vs. large, pistol vs. rifle)

- Use a priming tool, which may be part of your press or a separate hand tool

- Ensure primers are seated flush with or slightly below the case head

- Avoid crushing primers during installation, as they contain sensitive explosive compounds

Primers are the ignition source for your ammunition, so proper installation is critical. A new primer will provide reliable ignition and consistent pressure.

Measuring and Adding Powder

With primers installed, you’ll next add the powder charge:

- Consult your reloading manual for the appropriate powder type and amount for your specific bullet weight and caliber

- Set up your powder measure to dispense the correct charge

- Verify the weight using a scale, especially for rifle cartridges or precision loads

- Funnel powder into each primed case, maintaining consistent powder levels

- Visually inspect each case to confirm powder is present but not overfilled

The amount of powder used directly affects pressure and velocity. Always follow published load data and start with charges on the lower end of the recommended range when developing new loads.

Seating Bullets

The final assembly step involves placing and seating the bullet:

- Select your bullets (lead bullet, soft point, or other types depending on intended use)

- Adjust your seating die according to your reloading manual specifications

- Place a bullet in each powder-filled case

- Use the press to seat the bullet to the proper depth

- Check the overall cartridge length with calipers

Seating depths affect how a bullet engages the rifling in your barrel, which impacts both pressure and accuracy. Different bullets may require different seating depths even in the same caliber.

Crimping (If Necessary)

Some loads benefit from crimping to secure the bullet in place:

- Determine if your load requires a crimp (often needed for heavy recoiling loads)

- Use a separate crimping die or the crimping feature on your seating die

- Apply just enough crimp to hold the bullet without deforming it

- Check that the case mouth properly secures the bullet without excessive pressure

Over-crimping can cause high-pressure signs and accuracy problems, while under-crimping may allow bullets to move during recoil or feeding.

Final Inspection

Before storing your completed ammunition:

- Visually inspect each round for proper assembly

- Verify consistent overall length

- Look for any abnormalities like cracks, bulges, or improperly seated primers

- Check for correct headstamp and caliber marking to avoid mixing ammunition

This methodical approach to reloading ensures consistency across your ammunition. Record keeping is also valuable—note the components, measurements, and performance of your loads for future reference. For serious reloaders, especially those making ammunition for precision rifle competition or specialized hunting loads, these records help refine future batches.

Safety Considerations When Reloading

Safety Tip #1: Follow Published Load Data

Reloading ammunition requires strict adherence to safety protocols. Always follow published load data from reliable reloading manuals, never exceeding maximum powder charges or substituting powders. Starting with lower charges and working up gradually allows you to monitor for pressure signs while developing safe loads.

Safety Tip #2: Avoid Distractions

The reloading process demands your complete attention. Set up in a quiet, well-lit area away from distractions and avoid interruptions during critical steps like powder charging. Double-checking your work frequently helps prevent potentially dangerous errors.

Safety Tip #3: Recognize Pressure Signs

Learn to recognize warning signs of excessive pressure, including flattened primers, shiny ejector marks on the case head, difficult extraction, and unusual report when fired. If you observe any pressure signs, stop shooting immediately and review your reloading process.

Safety Tip #4: Store Components Properly

Proper storage of components is essential for safety. Keep powder and primers in original containers, store them separately, and protect them from heat, moisture, and ignition sources. Label all reloaded ammunition clearly and store it in appropriate containers to prevent mix-ups and degradation.

Get Everything You Need for Shooting and Reloading from Berry’s

When it comes to reloading your own ammunition, using quality components makes all the difference in performance and reliability. Berry’s Bullets offers over 80 types of superior copper-plated bullets designed for consistent performance in various shooting applications. Whether you’re loading for target practice, hunting, or precision rifle competition, Berry’s has bullets that will meet your specific needs.

Beyond bullets, Berry’s provides all the essential reloading tools to make your process more efficient. Our primer flip trays, case lube, powder funnels, and bullet pullers are designed by reloaders for reloaders, ensuring practical functionality. For brass preparation, Berry’s offers complete brass cleaning solutions, including tumblers, polish, media, and media separators that thoroughly clean your brass casings without damaging them.

Quality components lead directly to better accuracy and more consistent ammunition. When you’re investing time in the reloading process, starting with premium bullets and using proper tools yields better results. Whether you’re reloading to save money on factory ammunition, create loads for an obscure cartridge, or develop custom ammunition for your specific firearm, Berry’s Bullets has the components and tools to help you achieve excellent results with every round you load.